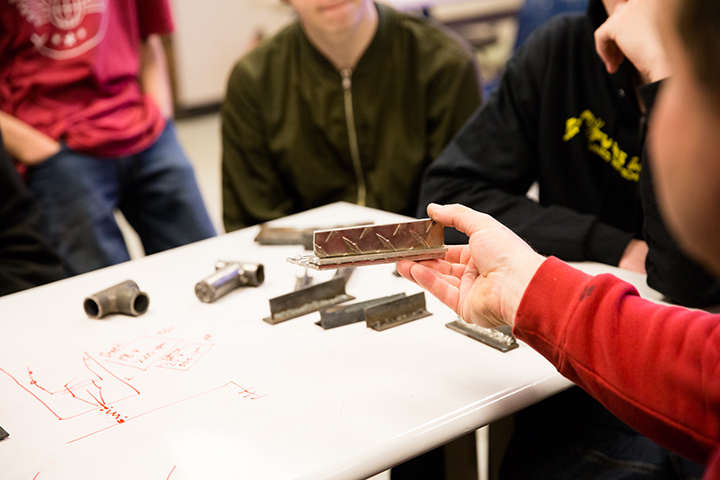

First photo, from left: Staff members Craig Witt and Julio Valencia learn techniques from a Fort student. Second photo: Witt, center, practices under the guidance of a Fort student while Valencia and Sam Bauder observe from behind. Third photo: Teacher David Richard demonstrates. Fourth photo, from left: Students Nathan Lampe and CJ McCombs demonstrate a wire feed machine. Fifth photo, from left: Lampe and Bauder. All photos by Cheryl Boatman.

Learning never stops

The three welders huddled near one of the bays in the welding and fabrication shop at Fort Vancouver High School Center for International Studies. Under the guidance of a more experienced welder, the students learned basic techniques on a wire feed machine. Not unlike any other day in the shop.

But these weren’t your typical students. They all work in the Vancouver Public Schools facility support service center and have varying welding experience. Their teachers—the teens enrolled in Fort’s welding program and their teacher, David Richards—were ready to fill in the gaps. The new partnership is part of expanded access to professional development opportunities for the people who maintain our buildings, who have a growing interest in finding ways to incorporate their work with classroom learning. Among them are electricians Craig Witt and Julio Valencia, who saw an opportunity in the welding program to fuse existing resources by bringing service center staff members into the classroom to both learn and mentor in a positive way.

“How cool would that be for a 17-year-old, 18-year-old kid to get to teach some old curmudgeons what they know?”

“They have to actually do mentor hours. We’re like, OK. Win-win then. They get their mentor hours and we learn something that we could use out here.”

With the knowledge gained in Fort’s shop, staff members can apply their skills to projects that impact schools all over the district, such as repairing lunchroom tables, retrofitting dumpsters and installing new emergency exit signs.

Throughout the school year, there will be opportunities at Fort for staff to learn new skills that will save the district money through empowering our folks to perform intricate work that would otherwise be contracted out. Additionally, the students can hone their own skills through teaching, says Craig.

“You know, it’s one thing if you think you know something. But if you have to teach it, then you’d better know what you’re talking about. And if you can teach it, you really do know the subject matter.”

One of the student-instructors is junior CJ McCombs. CJ speaks like a veteran welder. With two years in the program under his belt, he’s got the chops to back it up.

“.035 flux core. It is a wire that is fed through a hose with inert gas to make sure the metal can’t brittle when exposed to air.”

While he’s still in high school, CJ can envision how his skills will pay off in the future:

“It really pays well to learn a technical skill; it doesn’t even have to be welding. It can be electrician; it can be plumbing.”

The welding program is a unique opportunity for students to learn in an employment-like environment that can lead to jobs as soon as they graduate from high school. The standards are high—students’ grades must be at least a B to continue each semester—but so is the demand. Last year, all of the program’s 28 slots were filled, with seven additional students being placed on a waiting list.

“It’s really something special these kids get to do. A lot of kids don’t have this sort of opportunity to learn these skills. It’s something I wish I would have pursued at their age.”

That’s Sam Bauder, a boiler technician, for whom the chance to learn from welding students and David Richards is a professional advantage.

“A lot of the stuff I learn here will be helpful to learn better skills to better serve the district, to help do some of the repairs we do. I’ll be able to do it to a higher quality.”

It also reinvigorates enthusiasm for their work, said Craig.

“We come away from there jazzed.”

After all, learning doesn’t stop at the end of the day, or when you graduate. It continues well into adult life: at home, out in the world and on the job. We here at VPS may work in education, but we all are always learning. And I am impressed and inspired when I see it happening.

Take care,